Toyota is now considered the leader in Lean Management. The company has revolutionized production and logistics management by developing and building a Lean Management philosophy at its sites. This approach is based on continuous identification and elimination of waste from processes and supply chains [Liker 2004]. Waste is understood as all activities that do not add value. In the classic approach defined by Toyota, there are seven types of waste [Liker 2004]:

- unnecessary transport – i.e. moving parts of semi-finished products, products more often than necessary,

- excessive inventory – that is, the storage of too many materials, semi-finished products, work in progress and finished products,

- unnecessary movement – i.e. excessive traffic associated with poor organization of workstations,

- waiting – understood as inactivity of people, machines and other resources,

- overproduction – i.e. producing more than necessary at a given moment (than it results from the customer’s orders),

- overprocessing – i.e. performing unnecessary steps and activities in the process,

- defects and deficiencies – both in relation to the products being manufactured and the documentation, information transfer, etc.

Currently, in addition to the types of process losses described above, there are two additional types of waste [Shook 2012]:

- wasting potential – misusing the knowledge, skills and talents of employees,

- blaming – seeking and punishing people who carry out activities that do not add value to the process, instead of improving the process.

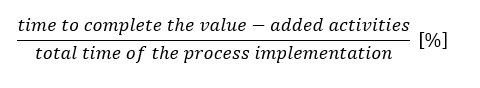

According to the Lean philosophy, the process therefore measures the percentage of value added in the process, according to the formula [Liker 2004]:

One of the creators of Toyota’s production system, Taiichi Ohno, described the concept of adding value to the process as such: „Everything we do is to reduce the time from the moment the customer places the order to the moment we get the money, we constantly reduce that time by eliminating waste” [Ohno 2008]. This means that all employees of the company are involved in continuous improvement of processes, through continuous identification of waste and elimination of its causes [Imai 2006, 2007]. The Lean approach assumes that improving something without removing the source is nothing more than transferring waste to another place [Laraia, Moody and Hall 1999].

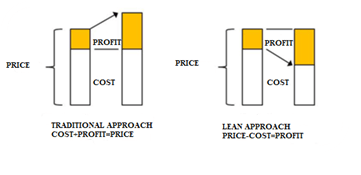

By eliminating waste, Toyota is therefore able to handle more orders with unchanged resources. For your business, this means you can make more profit without increasing your customer’s price. Indeed, the traditional approach to product pricing assumes that a profit margin should be added to the costs incurred by the manufacturer. Increasing the profit of the company is therefore only possible by increasing the margin and thus the price to the customer. According to the Lean philosophy, by eliminating waste, it is possible to reduce production costs while increasing productivity [Womack, Jones and Roos 2008]. The difference between these approaches is shown in Figure 6.

Through the commitment of all employees to the continuous pursuit of process excellence, Toyota has become a leader in the highly competitive automotive market. In the 1950s, when Japan was in the midst of

a post-war crisis and Toyota started building its Lean philosophy, the company’s annual production volume was around 200 cars. At the same time, the Ford factory in Detroit was producing 7,000 cars a day. Today, with its ability to continuously improve processes, Toyota is the global automotive market leader, selling 9,748 million cars worldwide every year. Sales of Toyota vehicles are also characterized by the highest growth rate, which in 2011-2012 amounted to 22.6% [Shook 2012]. In 2014, Toyota sold over 10 million cars during the year [Ocetkiewicz 2015].

One of the key wastes singled out in Lean philosophy is „overstock”. Therefore, in the following section of the book, we will discuss the tools for managing inventories with the aim of determining the level of inventories that will not constitute surplus inventories and the waste associated with them.

Kontakt

Smart Project S.K.A.

ul. Libelta 27/A3.1

61-707 Poznań

NIP: 7811878786

REGON: 302125920

Telefon

Na skróty

- Jak się przygotować do projektu WMS – lista kontrolna przed rozpoczęciem projektu wdrożeniowego

- Cyfrowa transformacja przy użyciu prostych i ogólnodostępnych narzędzi

- Kryzys to szansa. Lekcja zwinności biznesowej od OTIF Profil. Rozmowa z Łukaszem Pietraszakiem

- Czy zaufanie może stać się narzędziem dorównującym technologii?

- Procesy nas utrzymują, projekty nas rozwijają. Jak zarządzać innowacjami w sercu produkcyjnej organizacji?